What are the benefits of using Waterjet CNC cutting technology for your metal fabrication needs?

If you are looking for a reliable and efficient cutting method for your metal fabrication needs, you should consider waterjet CNC cutting technology. It has become increasingly popular in the metal fabrication industry due to its versatility and precision.

Waterjet cutting is capable of cutting a wide variety of materials, including metals, plastics, ceramics, composites, and more. This technology uses a high-pressure jet of water and abrasive materials to cut through the material with high precision, creating clean and accurate cuts.

One of the main benefits of waterjet CNC cutting technology is its ability to produce complex shapes and designs. This makes it an ideal choice for custom fabrication projects. It is also a great option for producing small or large batches of parts with high accuracy and repeatability.

Another advantage of waterjet cutting is that it produces a narrow kerf, which means less material is wasted during the cutting process. This is important for keeping costs down and reducing material waste.

Waterjet CNC cutting technology is also environmentally friendly because it uses only water and abrasive materials to cut through the material. There are no hazardous fumes or chemicals produced during the cutting process, making it a safe and clean option for metal fabrication.

In conclusion, waterjet CNC cutting technology is a versatile and efficient cutting method for metal fabrication needs. Its precision, versatility, and ability to produce complex shapes make it an ideal choice for custom fabrication projects. If you want to revolutionize your metal fabrication process, consider using waterjet CNC cutting technology.

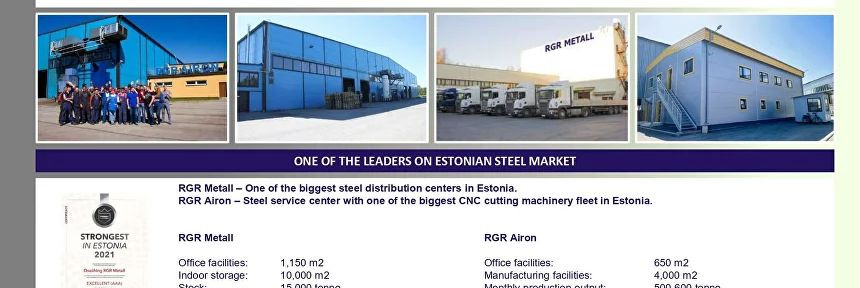

If you're interested in learning more about waterjet CNC cutting technology and how it can benefit your metal fabrication projects, don't hesitate to contact us at RGR Airon!

Kommentaarid (0)